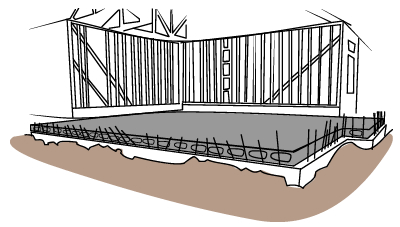

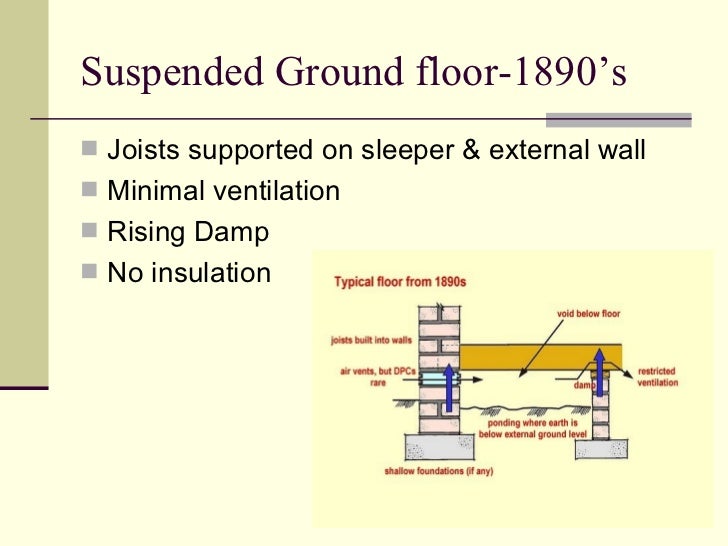

🕑 Reading time 1 minuteConcrete floor slab construction process includes erection of formwork, placement of reinforcement, pouring, compacting and finishing concrete and lastly removal of formwork and curing of concrete slab ContentsConcrete Floor Slab Construction Process1 Assemble and Erect Formwork for Slab2 Prepare and Place Reinforcement for Slab3 Pour,Ground bearing slabs should not be used in ground conditions where heave can occur or where the foundation depth is greater than 15m Under these circumstances a suspended floor construction should be used Site preparation The ground beneath the floor should be stripped of all topsoil, organic matter or tree roots prior to filling and compaction Traditional ground floors have consisted of little more than a few flagstones or bricks placed directly over the soil The Victorian era saw the widespread introduction in mass housing with suspended timber floors, alongside rudimentary solid floors in hardwearing areas such as kitchens and hallways This combination persisted well into the 1930s, with solid concrete

Insulation For Solid Concrete And Suspended

Suspended in situ concrete ground floor slab

Suspended in situ concrete ground floor slab- Suspended slab may be the most expensive compared to Suspended ground floors – where the slab is supported on beams and/or loadbearing sleeper walls and is not in direct contact with the ground Suspended slab under construction, with the formwork still in placeA suspended ground floor is one of the leading causes of heat loss within older homes But there is a way to prevent energy loss and keep out the cold Suspended floor insulation can help to ensure a room retains heat and is energy efficient Read on to find out all about our applications and everything else you need to know

Builder S Engineer Suspended Ground Floor Slabs

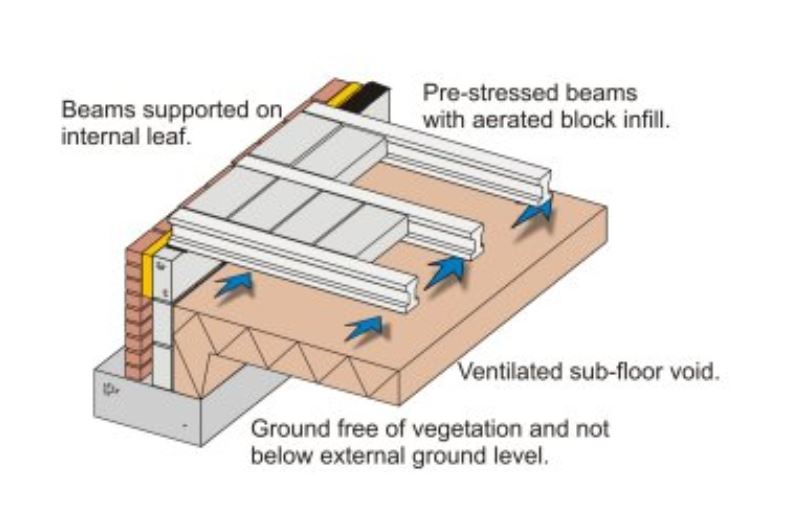

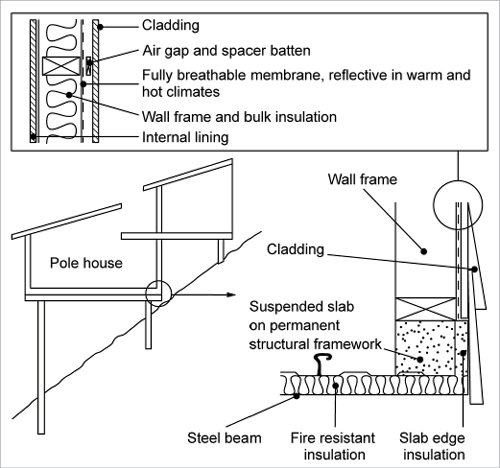

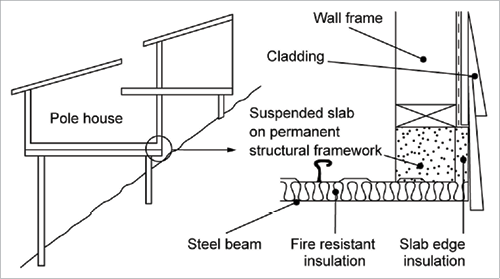

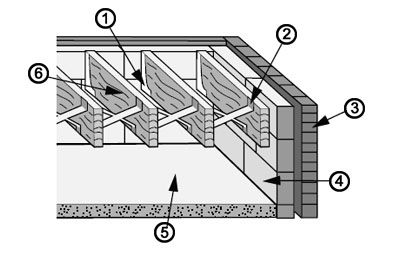

A suspended floor is a ground floor with a void underneath the structure The floor can be formed in various ways, using timber joists, precast concrete panels, block and beam system or cast inA suspended concrete floor is a floor slab where its perimeter is, or at least two of its opposite edges are, supported on walls, beams or columns that carry its self weight and imposed loading The floor spans between supports and will normally deflect under load to a dimension that is limited by the design usedSuspended Concrete Slab Suspended concrete slab is referred to a cement slab that is not in contact with the ground This type of concrete slab construction requires different concrete slab design from the one we normally see that is cast on the ground The most common application of suspended slab in residential construction is used at garage floor where below the garage floor

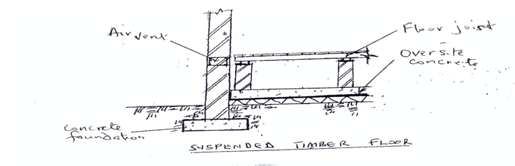

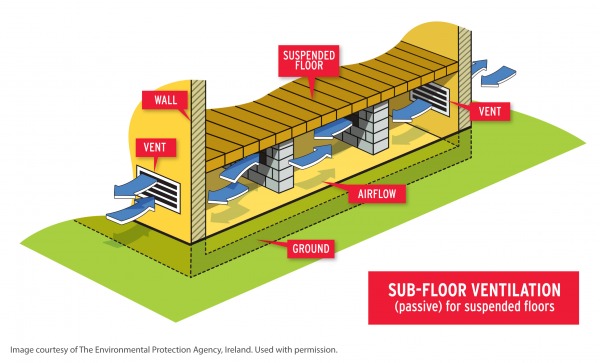

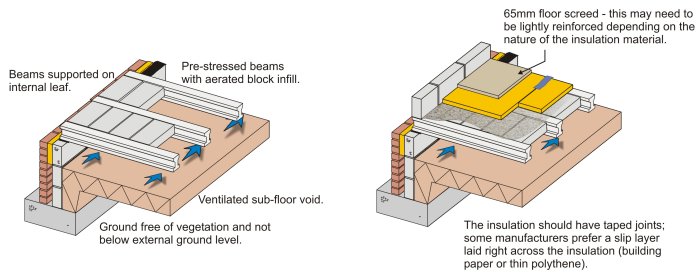

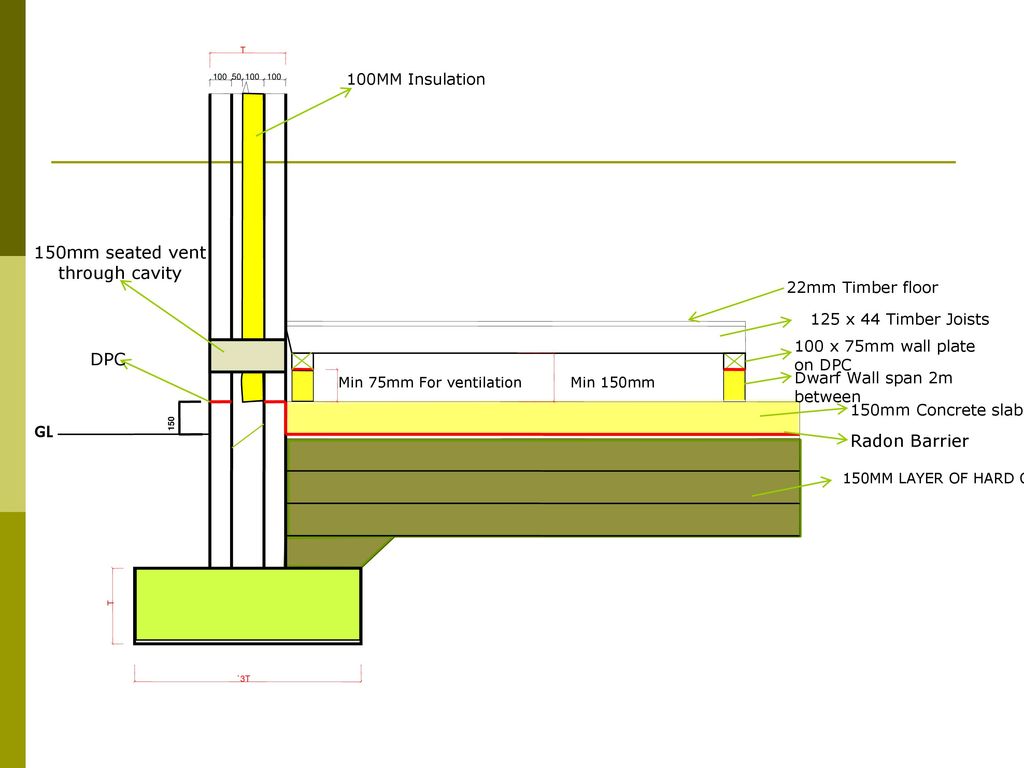

For slabonground floors it provides an understanding of the footing/slab selection, design, detailing and construction requirements contained in AS 2870 and the Housing Provisions of the BCA The requirements of AS are also covered For suspended floors it covers both upper floors and those at ground level where a slabonground may Firstfloor slab thickness The normal thickness used for reinforced concrete slabs in South Africa is 170 mm for small slabs, 255 mm for slabs larger than 5m x 5m and 340 mm thick for longspan slabs forming part of a beam and carrying heavier loads The thickness of a slab will depend on the use and span of the slabSuspended timber floor As a requirement of the Building Regulations the structure should be protected against the growth of weeds and other plantlife The ground should have a layer of concrete poured across and there should be a ventilated gap of at least 150mm between the underside of the timbers and the concrete, to prevent moisture gathering and affecting the

Due to possibility of movement in the ground surface make sure you use steel reinforcement mesh even though it is not suspended and use a waterproof membrane such as heavy unbroken plastic to stop water penetrating the underside of the slab Try tIt is assumed that the ground gives no support but simply acts as in situ formwork for the floor slab The design is the same as for suspended floors, using the approaches in BS 8110, now withdrawn and superceded by Eurocode 2 From a construction point of view, it is economic to transfer the slab loads directly to the piles without any beamThe Polyvoid slab is a suspended ground floor slab, that is designed for reactive soils and works by separating the slab from the reactive soilsThis slab wa

Materials For Basement Ceiling Floor Slab Insulation

Our Suspended Ground Floor Slab Express Concrete Facebook

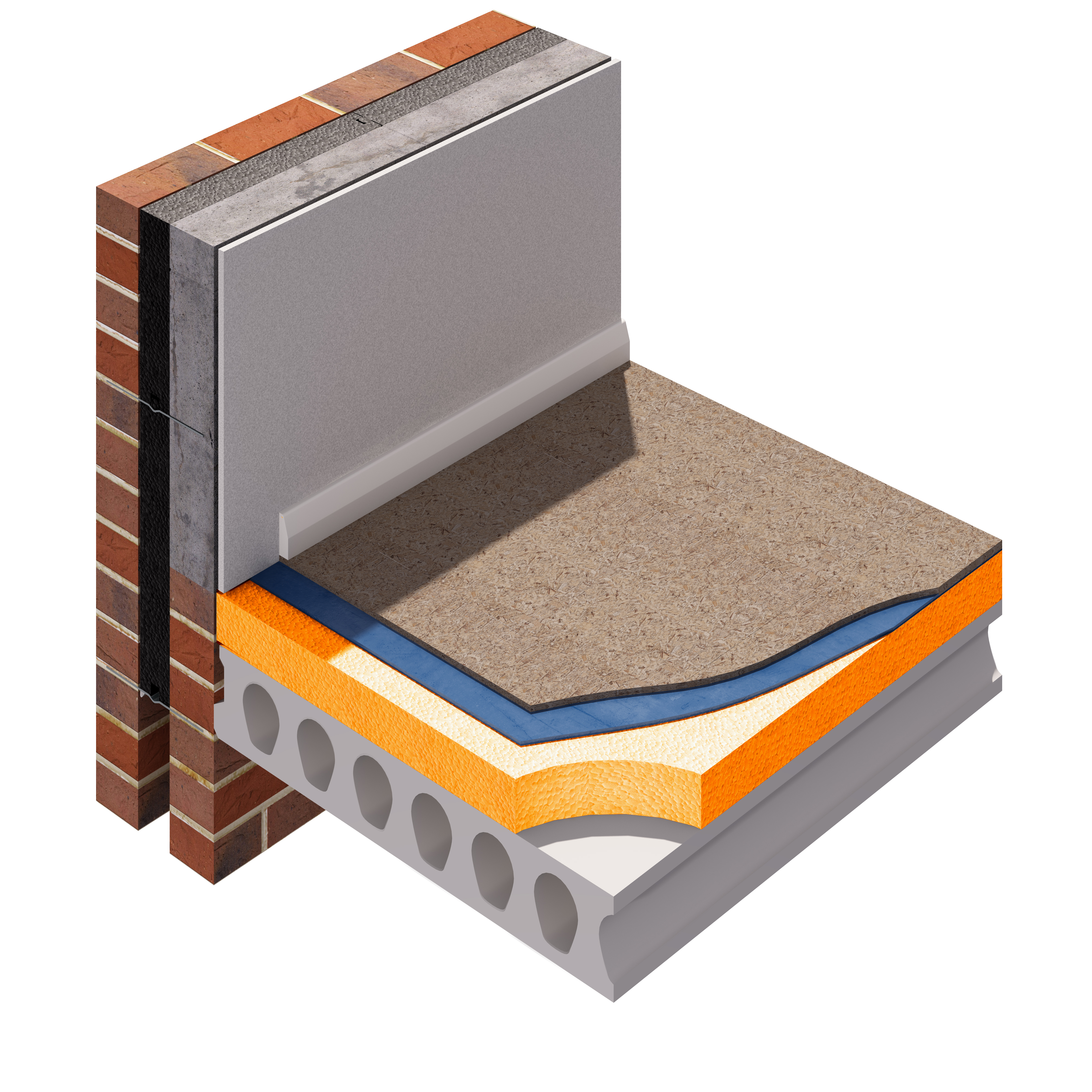

Suspended floors are also used when the water table is high, or when aggressive chemicals are present in the soil that may attack the concrete slab The ground floor is made up of suspended concrete slab or beam and block floor, supported by the external and internal load bearing walls, which transfer the loads to the foundations below Suspended Ground Floor Slabs For situations where the ground is unsuitable for the support of the ground floor slab or where the slope of the site makes it economic to leave a void below the ground slab, suspended floors are adopted Where a void is left below the slab, a precast floor system can prove economic and durable if suitable coverPrecast suspended ground floor Insulation above slab, with timber floor finish Ground Floor Insulation above slab DETAIL 401, 11 Ground Floor Insulation above slab Seal all penetrations through air barrier using a flexible sealant or tape Seal between wall and floor air barrier OR seal gap between skirting

Concrete Floor Slab Construction Process The Constructor

Suspended Floors All You Need To Know Thermohouse

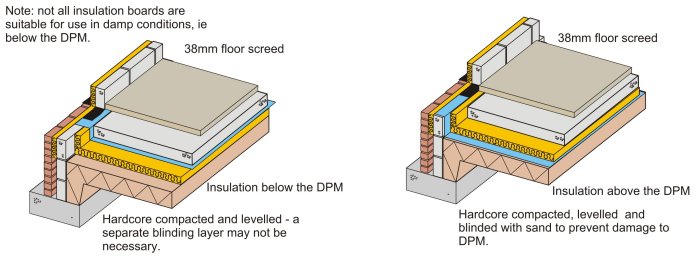

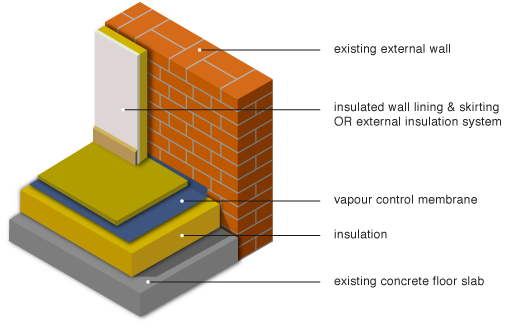

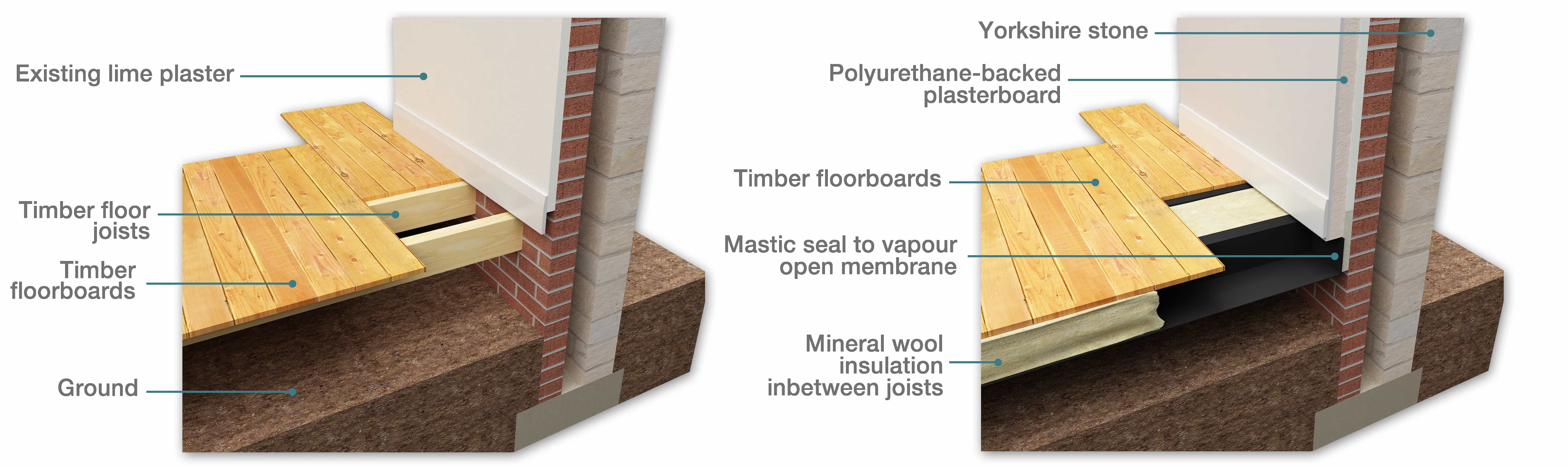

The floor right on top of the ground is called a ground bearing floor while everything else is suspended The insulation must be strong and waterproof The slabs needs to be of low conductivity material, so that the thickness of the insulation can be reduced It also needs to be able to withstand the load of the floor construction as well as A Best Practice Approach To Insulating Suspended Timber Floors Fintan from our Technical Team discusses the thermal loss issues associated with suspended timber floors and outlines a best practice approach to tackling them At the turn of the 18th century, when construction techniques moved from boarded floors installed directly on the groundIf embedded floor heating is incorporated in a concrete slabonground, the slab must be insulated so that heat from the slab is delivered up into the space above and not lost to the exterior and ground below Suspended ground floors â where the slab is supported on beams and/or loadbearing sleeper walls and is not in direct contact with the ground The design of suspended floors

E5smew23 Suspended In Situ Concrete Floor Insulation Below Slab Labc

Figure B 10 Figure B 10 Alternative Floor Slab Detail The Suspended Reinforced Concrete Garage Workshop Plans Workshop Plans Concrete

While the concrete ground floor slab is a common feature in New Zealand homes, suspended concrete floors have been slower to catch on outside commercial and architecturally designed homes However, suspended concrete floors offer many benefits for residential buildings, including excellent structural performance, thermal advantages and sound dampeningWhere a concrete floor slab is to be built on weak ground of poor supporting characteristics, it may be supported on concrete pile foundations or ground beams to prevent excessive slab settlement under imposed loading These slabs will have to be designed and reinforced as suspended floors Suspended Floors All you need to know What are they?

Insulation Below Ground Floor Slab Slab Insulation Floor Insulation Flooring

Building Guidelines Concrete Floors Slabs

NHBC requires ground floors to be constructed as suspended floors in the following situations where the depth of fill exceeds 600mm, as described in Chapter 51 'Substructure and ground bearing floors' (Design) where soil swelling may occur, as described in Chapter 42 'Building near trees' on sites which have been subject to vibratory groundSuspended ground floor slab; Suspended slabs are aboveground level slabs which are not directly in contact with the earth They are commonly used to create floors for the upper storeys of houses, but can also be sat on top of preconstructed walls to form a ground floor

Benefits Of A Suspended Floor The Shed House

Mg3 External Masonry Cavity Wall Suspended Concrete Slab Detail Library

Many translated example sentences containing "suspended ground floor slab" – SpanishEnglish dictionary and search engine for Spanish translationsFlooring ground floor slab construction Guide to Laying a Concrete Floor slab and Preparing for a concrete floor slab Repairing Concrete Floors and Replacing a Timber Floor with Concrete After Dry Rot Foundations conservatory foundations How to build foundations for aRequirements and recommendations for suspended ground floors of insitu and precast concrete and timber joists 52 52 Chapter 52 Page 1 Suspended ground floors 13 DESIGN STANDARDS 52 D1 Design shall meet the Technical Insulation below the ground floor slab

Fastslab Ground Floor Renovation System

Suspended Timber Floor Detail Youtube

The only issue I have is NHBC, Checkmate and several google searches all prohibit fill of more than 600mm for a ground bearing slab, and I want to understand why the design standard of our design allows it and if I am going to experience excessive settlement in my floor or we need to change the design to be suspended off the inner block work and be less reliant on the fillGround floor – suspended floor decks Suspended ground floor decks – for example, a block and beam floor, or precast concrete plank – are an efficient way of providing a level floor on plots with poor ground or steep slopes, where too much ground fill is required to pour a groundbearing concrete slabSuspended slabs are aboveground level slabs which are not directly in contact with the earth They are commonly used to create floors for the upper storeys of houses, but can also be sat on top of preconstructed walls to form a ground floor

Floor Slab An Overview Sciencedirect Topics

How Are Suspended Slabs Built Build

These can be classed as either Suspended or Solid Solid floors are a lot more substantial and require the ground to be made up in layers of ground sub base, sand, compacted hard core, damp proof membrane, insulation and concreteSUSPENDED CONCRETE FLOOR 5 FASTER LIGHTER EASIER INTRODUCTION LIGHTER, FASTER, EASIER APPLICATION COMPONENTS Speedfloor combines a concrete slab with a rollformed galvanised steel joist for permanent structural support, using the properties of the concrete and the steel to their best advantage The joist depth and theFloor slab Designing Buildings Wiki Share your construction industry knowledge The term 'floor slab' usually refers to a floor that has been formed using concrete (and generally steel reinforcement) and may form part of the structure of a building It may form the floor of a basement, at ground level or at upper levels It will be typically reinforced, either by rebar or

Suspended Floors All You Need To Know Thermohouse

Ground Floors Wall Concrete

Concrete slabs that do not come into contact with the ground can be differentiated into two types and Sephaku Cement is here to explain how suspended concrete slabs vary from ground concrete slabs Ideally used in roofing or floors that are suspended above ground level, while these are the two most common uses of suspended concrete slabs, these floatingThis chapter gives guidance on meeting the Technical Requirements for suspended ground floors including those constructed from insitu concrete precast concrete timber joists 521 Compliance 522 Provision of information 523 Contaminants The FastSlab Ground Floor system is designed to make it quick and easy to replace existing suspended ground floors with an insulated concrete or screeded floor This gives the solid feel of a concrete ground floor with the benefit of maintaining the ventilated void beneath to prevent moisture issues in the existing walls

Suspended Ground Floors Suspended Timber Floor 800x400 Png Download Pngkit

Concrete Slab Wikiwand

Concrete vs Timber Floors There are 2 types of floor construction used in the building industry today; Suspended floors can be either concrete beam and block or timber, but I can think of any advantages of using timber other than for DIY and easy to lift/move materials With a suspended floor you would have a concrete oversite (slab) over the ground beneath the floor or you could lay a ground sheet and gravelThe slab can be walked on after 3 days, but avoid heavy loads for at least 7 days At Foilboard, we develop leading insulation materials for Australian commercial and residential properties Our under slab insulation product, Slabmate, is the new under slab insulation solution for slabonground

Our Suspended Ground Floor Slab Express Concrete Facebook

Response Of Building Systems With Suspended Floor Slabs Under Dynamic Excitations Sciencedirect

Uvalues of ground floors and basements 6C0 Introduction For new buildings a ground floor should not have a Uvalue exceeding 025 W/m2K, This may only be achieved without the need for insulation if the perimeter to area ratio is less than 012 m/m2 for solid ground floors or m/m2 for suspended floors However, some ground floorSuspended Ground Floor Slab Reinforcement construction409 Suspended ground floor slab insulation below slab Wallground floor junction Scottish Building Standards Steel frame 017 013 E5 0137 09 410 Ground bearing floor slab insulation above slab Wallground floor junction Scottish Building Standards

Concrete Slab Abis

Borders Underfloor Heating Supply Water Filled Underfloor Heating For Concrete And Suspended Timber Floors

A suspended concrete floor is a floor slab where its perimeter is, or at least two of its opposite edges are, supported on walls, beams or columns that carry its self weight and imposed loading The floor spans between supports and will normally deflect under load to a dimension that is limited by the design used Suspended slabs are upper floors of the ground that do not come into direct contact with the Earth They are often used to build floors for the upper stories of the house, but they can also be laid on top of the prebuilt walls to form a floorInsitu concrete suspended ground floors (December 08) (First issue) TECHNICAL GUIDANCE 52/01 Sketch A Sketch B DPM turned back over top of slab DPM cut off at bottom of floor slab Page 1 of 1 HB2851 01/ NHBC, NHBC House, Davy Avenue, Knowlhill, Milton Keynes, Bucks MK5 8FP Tel 0344 633 1000

Evolution Of Building Elements

Detail Post Floor Details First In Architecture

Slabs transmit the applied floor or roof loads to their supports Slabs may be classified into two main groups depending on whether they are supported on the ground or suspended in a building Ground slabs Ground slabs are those slabs that are poured directly into excavated trenches in the ground Nuspan is a high performance, precast, insulated flooring system for application in the construction of suspended ground floors in new build housing and small scale commercial buildings With a saving of up to five times the amount of onsite labour, it's no wonder Nuspan insulated precast concrete units (IPCU) have become a nationwide leading Modern Method of

Builder S Engineer Suspended Ground Floor Slabs

Insulation For Solid Concrete And Suspended

Suspended Concrete Slab Suspended Slab Cement Slab

Diagram Of Suspended Timber Floor With Underfloor Heating Pipes Underfloor Heating Floor Heating Systems Hydronic Radiant Floor Heating

Insulating Below Suspended Timber Floors Ballytherm Ie

Method Statement For Construction Method Statement Non Suspended Slab

Articles And Advice Insulation Kingspan Great Britain

Detail Post Floor Details First In Architecture

Building Guidelines Concrete Floors Slabs

5 Things To Look For When Inspecting A Suspended Concrete Slab

E5mcpf32 Suspended In Situ Concrete Floor Insulation Below Slab Labc

Lightweight Suspended Concrete

Technical Hub Insulation Boards Kingspan Ireland

Fbe 03 Building Construction Science Lecture 3 Floor

Concrete Slab Floor Construction Branz Renovate

Suspended Slab Subfloor Build

Types Of Ground Floors

1

This Seminar Covers The Principles Design And Installation Of Ground Bearing And Suspended Insulated Floors You Will Discover Pdf Free Download

E5mcff30 Suspended In Situ Concrete Floor Insulation Below Slab Labc

Builder S Engineer Design Of Foundations At Pile Head

Floors

Floors And Flooring Sans Building Regulations South Africa

Concrete Slab Or A Timber Joisted Floor Which Is Best Partridge

Insulation For Ground Floors Designing Buildings Wiki

Ground Floor Insulation Below Concrete Slab Polyfoam Xps

Suspended Floors All You Need To Know Thermohouse

Ground Floors Archives Detail Library

Concrete Vs Timber Floors

Ground Bearing Floor Slab 650x368 Png Download Pngkit

Suspended Ground Floor Slab Reinforcement 3d Warehouse

Suspended Floors All You Need To Know Thermohouse

Greenspec Housing Retrofit Ground Floor Insulation

Masonry Cavity Wall Insulation Illustrations Building Insulation Drywall

5 1 7 Fill Below Floors Nhbc Standards 21 Nhbc Standards 21

First Floor Concrete Slabs What You Need To Know Eco Built

Floors And Flooring Sans Building Regulations South Africa

5 Types Of Concrete Slabs Construction Uses

Concrete Slab Floors Yourhome

Insulation Below Suspended Timber Floors Design Guidanceballytherm Co Uk

Farm Structures Ch5 Elements Of Construction Floors Roofs

Replacing Suspended Timber Floor

Eurima Suspended Concrete Floors

Building Construction Paper 2 Nov Dec 11

Greenspec Housing Retrofit Ground Floor Insulation

What Are The Spacing Of Reinforcement Bar In A Suspended Slab 6mx4m Quora

5 1 18 Laying The Ground Bearing Floor Slab Nhbc Standards 18 Nhbc Standards 18

Suspended Slabs

A Best Practice Approach To Insulating Suspended Timber Floors Ecological Building Systems

Suspended Ground Floor Slab Reinforcement Avi Youtube

Suspended Floors All You Need To Know Thermohouse

Suspended Ground Floor Construction Mezzanine Floor Supplier And Installers Prestressed Concrete

1

Insulating Suspended Timber Floors Green Building Store

Evolution Of Building Elements

Ground Floors Concrete And Suspended Timber Types Of

Underfloor Insulation Knauf Insulation

Types Of Ground Floors Ppt Download

Detail Post Floor Details First In Architecture

Concrete And Suspended Timber Ppt Download

Build Diy Suspended Concrete Ground Floors

Technical Hub Insulation Boards Kingspan Ireland

Concrete Slab Floors Yourhome

Building Guidelines Concrete Floors Slabs

Ground Floors Archives Detail Library

P1pcff4 Suspended Concrete Floor Insulation Below Slab Labc

1

Floor Structure Guide Flooring Concrete Floors Building A House

Suspended Floor Insulation Saint Gobain Insulation Uk

5 1 Damp Proofing Concrete Floors Nhbc Standards 21 Nhbc Standards 21

How To Choose A Floor Structure Homebuilding

First Floor Concrete Pouring In Site 1 Part 2 Youtube

6 Ground Floors Construction Studies

1

Soundproofing Guidelines For Approved Document E Compliance

Building Guidelines Suspended Timber Floors

Concrete Vs Timber Floors

Fastslab Ground Floor Renovation System

Concrete Slab Wikiwand

Concrete Slab Floors Yourhome

0 件のコメント:

コメントを投稿